1.The running characteristic is continuous pulsation type. there are dynamic type and static type according to casting method.

1.It can be customized according to customer's requirements as per open casting line with 1 or 2 molding machines.

2.Advance technology idea, reasonable processing requirements. good stability and high performance of automation.

3.Decrease labor intensity, improve the working environment, reduce the waste of raw and auxiliary materials,environmental-friendly.

Technical Parameter:

NO. | Name | Brand | Remark |

1 | Programmable Logic Controller PLC | mitsubishi | |

2 | HMI | mitsubishi | |

3 | Intermediate relay | Schneider | |

4 | AC contactor | Schneider | |

5 | power switch button | Schneider | |

6 | transfer switch | Schneider | |

7 | breaker | Schneider | |

8 | indicator light | Schneider | |

9 | Photoelectric switch/proximity switch | Omron | |

10 | switching power supply | Mean Well Taiwan | |

11 | cylinder | SMC (Japan) | |

12 | electromagnetic valve | SMC (Japan) | |

13 | triplets | SMC (Japan) |

Technical Characteristics:

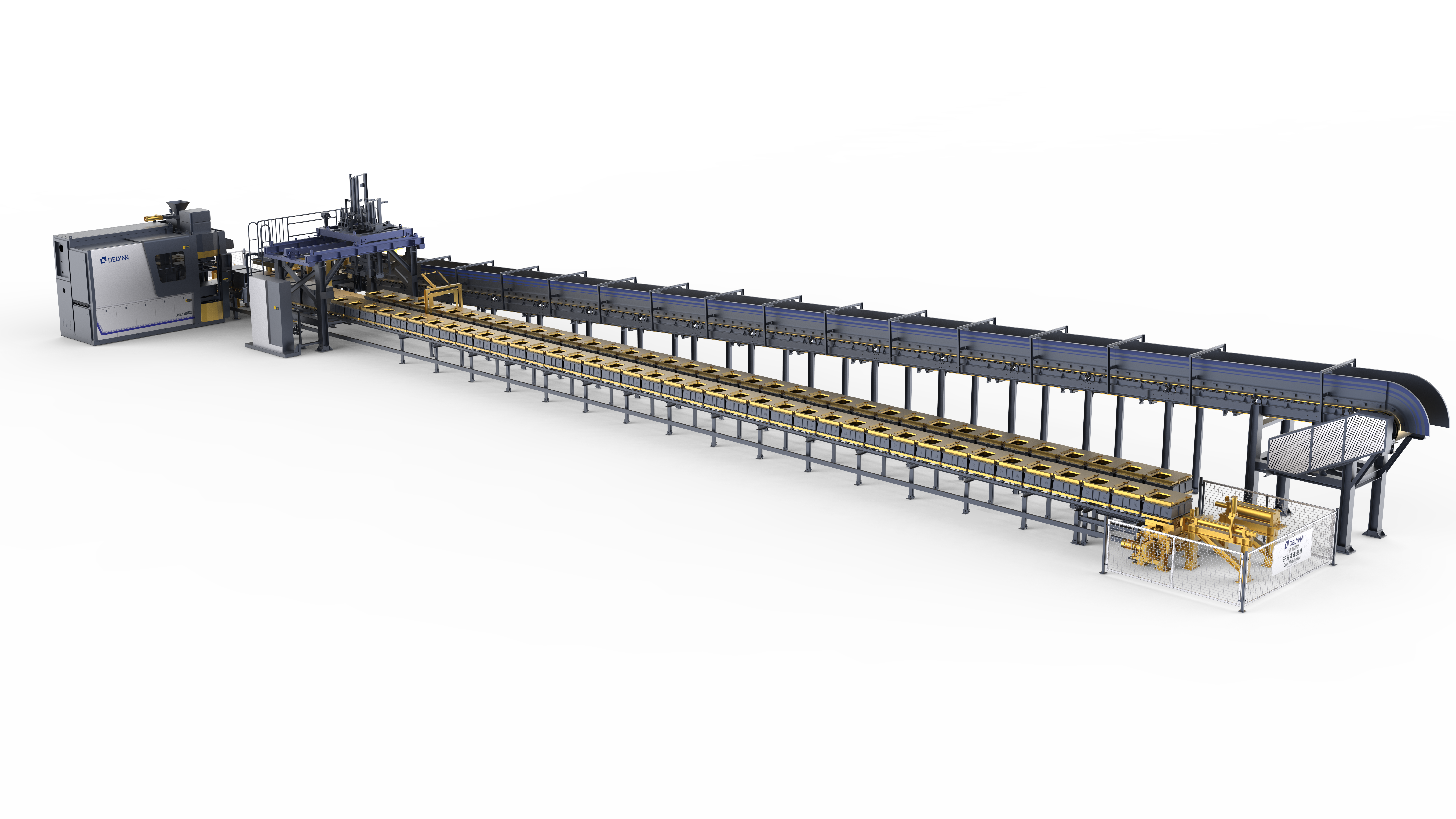

1. Cast open conveyor line (Open Line in short) is a mechanized conveying equipment that connects the various manufacturing process sections (molding, casting, cooling, etc.) in the foundry workshop to form a production line.

2.The running characteristic are continuous pulsation type. there are dynamic type and static type according to casting method.

3.Single-host open-type cable and dual-host open-type cable can be provided according to user needs

4.Advanced technical concept, reasonable process requirements, good stability and high degree of automation.

5.Reduce labor intensity, improve labor environment, reduce cost waste of raw and auxiliary materials, green environmental protection

Our Service:

We have strict management system,complete quality guarantee system and fine pre-sale and after-sale service system.

1.Pre-sale Service System

Please do not hesitate to contact with us If you are interested in machine. We can design the machine you requirements.

2.After-sale Service System

24/7 on line,including mobile/wechat/whatsapp etc. Our technician is available to visit and go to your place,and they will help your side for installation,maintenance,and training.

3.Payment

30% Deposit by TT,and The rest 70% by photos or you can check the quality on our factory before they shipment.

1.The running characteristic is continuous pulsation type. there are dynamic type and static type according to casting method.

1.It can be customized according to customer's requirements as per open casting line with 1 or 2 molding machines.

2.Advance technology idea, reasonable processing requirements. good stability and high performance of automation.

3.Decrease labor intensity, improve the working environment, reduce the waste of raw and auxiliary materials,environmental-friendly.

Technical Parameter:

NO. | Name | Brand | Remark |

1 | Programmable Logic Controller PLC | mitsubishi | |

2 | HMI | mitsubishi | |

3 | Intermediate relay | Schneider | |

4 | AC contactor | Schneider | |

5 | power switch button | Schneider | |

6 | transfer switch | Schneider | |

7 | breaker | Schneider | |

8 | indicator light | Schneider | |

9 | Photoelectric switch/proximity switch | Omron | |

10 | switching power supply | Mean Well Taiwan | |

11 | cylinder | SMC (Japan) | |

12 | electromagnetic valve | SMC (Japan) | |

13 | triplets | SMC (Japan) |

Technical Characteristics:

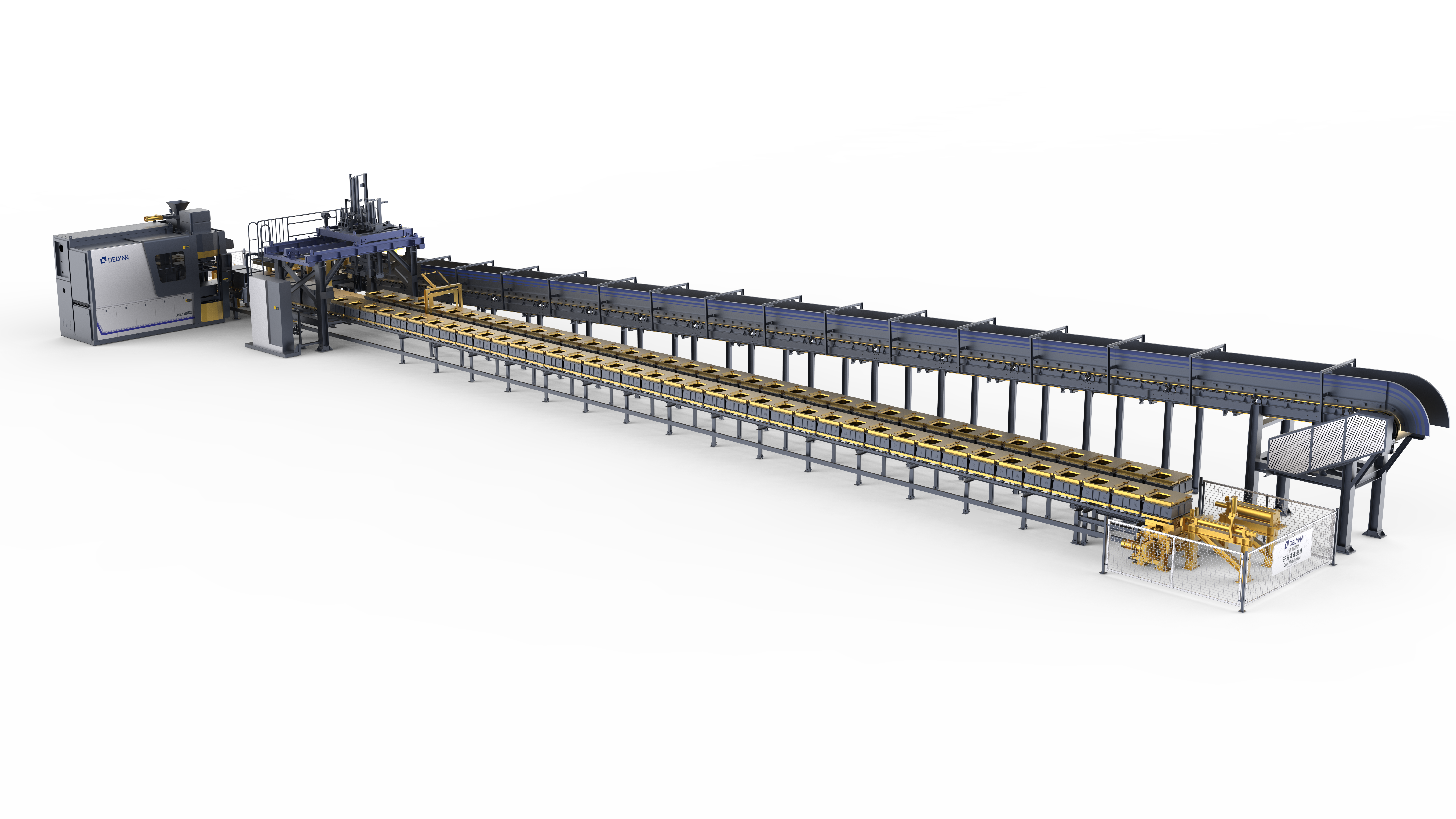

1. Cast open conveyor line (Open Line in short) is a mechanized conveying equipment that connects the various manufacturing process sections (molding, casting, cooling, etc.) in the foundry workshop to form a production line.

2.The running characteristic are continuous pulsation type. there are dynamic type and static type according to casting method.

3.Single-host open-type cable and dual-host open-type cable can be provided according to user needs

4.Advanced technical concept, reasonable process requirements, good stability and high degree of automation.

5.Reduce labor intensity, improve labor environment, reduce cost waste of raw and auxiliary materials, green environmental protection

Our Service:

We have strict management system,complete quality guarantee system and fine pre-sale and after-sale service system.

1.Pre-sale Service System

Please do not hesitate to contact with us If you are interested in machine. We can design the machine you requirements.

2.After-sale Service System

24/7 on line,including mobile/wechat/whatsapp etc. Our technician is available to visit and go to your place,and they will help your side for installation,maintenance,and training.

3.Payment

30% Deposit by TT,and The rest 70% by photos or you can check the quality on our factory before they shipment.