| Availability: | |

|---|---|

| Quantity: | |

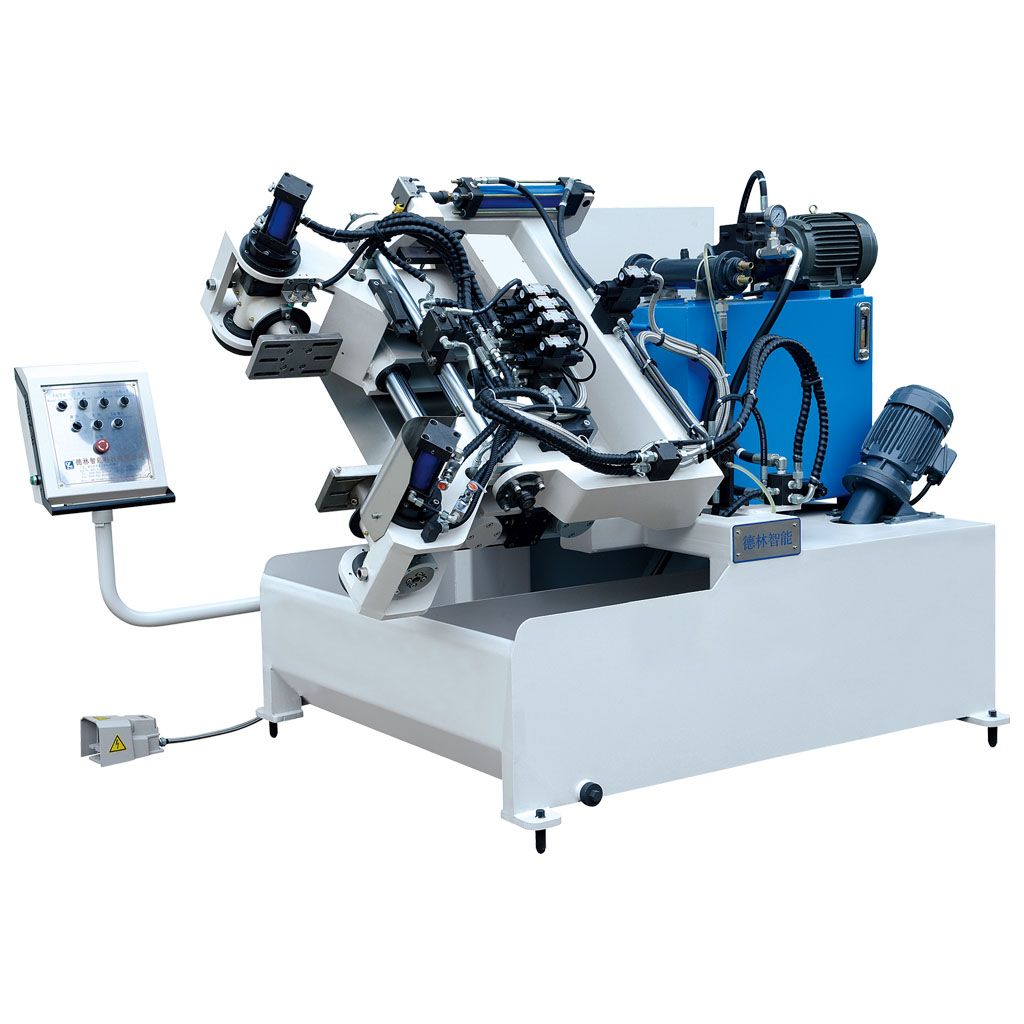

DLRT45(450 series)

DELYNN

Technical Parameters:

No. | Items | Parameters |

1 | Max. Size of Die | Φ450mm |

2 | Max. Weight of Die | 130kg |

3 | Max. Die Closing Stroke | ≤250mm |

4 | Hydraulic Pressure | 4-6MPa |

5 | Inclination for Side Pouring | 0-90˚ |

6 | Inclination for Frontal Pouring | 0-110˚ |

7 | Hydraulic Oil Volume | 163L |

8 | (Optional)Top Core Stroke | 20mm |

9 | Machine Power | 5.5kw |

10 | Net Weight | 1750kg |

11 | External Dimensions (L*W*H) | 2250*2160*1560mm |

Process composition:

Raise to a predetermined angle and place the sand core, step on the foot switch once (clamping) → casting → step on the foot switch once → timing after the clamping mechanism descends and returns to the original position → when the time is up, the mold is automatically opened → take out the product → switch Step on once → flip the mold clamping frame → mold rotation → mold lowering, rotating and cooling → mold rising → mold rotation return → mold clamping frame flipping back to position → worktable rising

Material selection:

1. The whole frame is made of QT450 castings, which is not easy to deform and has good toughness;

2. The lubricating part should be injected with general-purpose lithium-based grease with a dropping point of 193°C and a working penetration of 240. 3# general-purpose lithium-based grease lubricating oil is more resistant to high temperature than 2# and is used for heavy loads or vertical motor bearings. lubrication. The anti-wear hydraulic oil is 68#, and the new machine is replaced every three months, and then every eight months;

3. The coolant in the cooling pool is composed of graphite powder and water (about 850L);

4. High frequency quenching and chrome plating are used for mold clamping to improve surface hardness and durability;

5. The hydraulic system adopts Jiejia oil circuit, adopts Mitsubishi PLC and Schneider electric components, high-end configuration of first-line brands, quick response, and prolongs equipment life;

6. Equipped with Omron sensor to control mold clamping accuracy and low failure rate.

Our Service:

We have strict management system,complete quality guarantee system and fine pre-sale and after-sale service system.

1.Pre-sale Service System

Please do not hesitate to contact with us If you are interested in machine. We can design the machine you requirements.

2.After-sale Service System

24/7 on line,including mobile/wechat/whatsapp etc. Our technician is available to visit and go to your place,and they will help your side for installation,maintenance,and training.

3.Payment

30% Deposit by TT,and The rest 70% by photos or you can check the quality on our factory before they shipment.

Technical Parameters:

No. | Items | Parameters |

1 | Max. Size of Die | Φ450mm |

2 | Max. Weight of Die | 130kg |

3 | Max. Die Closing Stroke | ≤250mm |

4 | Hydraulic Pressure | 4-6MPa |

5 | Inclination for Side Pouring | 0-90˚ |

6 | Inclination for Frontal Pouring | 0-110˚ |

7 | Hydraulic Oil Volume | 163L |

8 | (Optional)Top Core Stroke | 20mm |

9 | Machine Power | 5.5kw |

10 | Net Weight | 1750kg |

11 | External Dimensions (L*W*H) | 2250*2160*1560mm |

Process composition:

Raise to a predetermined angle and place the sand core, step on the foot switch once (clamping) → casting → step on the foot switch once → timing after the clamping mechanism descends and returns to the original position → when the time is up, the mold is automatically opened → take out the product → switch Step on once → flip the mold clamping frame → mold rotation → mold lowering, rotating and cooling → mold rising → mold rotation return → mold clamping frame flipping back to position → worktable rising

Material selection:

1. The whole frame is made of QT450 castings, which is not easy to deform and has good toughness;

2. The lubricating part should be injected with general-purpose lithium-based grease with a dropping point of 193°C and a working penetration of 240. 3# general-purpose lithium-based grease lubricating oil is more resistant to high temperature than 2# and is used for heavy loads or vertical motor bearings. lubrication. The anti-wear hydraulic oil is 68#, and the new machine is replaced every three months, and then every eight months;

3. The coolant in the cooling pool is composed of graphite powder and water (about 850L);

4. High frequency quenching and chrome plating are used for mold clamping to improve surface hardness and durability;

5. The hydraulic system adopts Jiejia oil circuit, adopts Mitsubishi PLC and Schneider electric components, high-end configuration of first-line brands, quick response, and prolongs equipment life;

6. Equipped with Omron sensor to control mold clamping accuracy and low failure rate.

Our Service:

We have strict management system,complete quality guarantee system and fine pre-sale and after-sale service system.

1.Pre-sale Service System

Please do not hesitate to contact with us If you are interested in machine. We can design the machine you requirements.

2.After-sale Service System

24/7 on line,including mobile/wechat/whatsapp etc. Our technician is available to visit and go to your place,and they will help your side for installation,maintenance,and training.

3.Payment

30% Deposit by TT,and The rest 70% by photos or you can check the quality on our factory before they shipment.