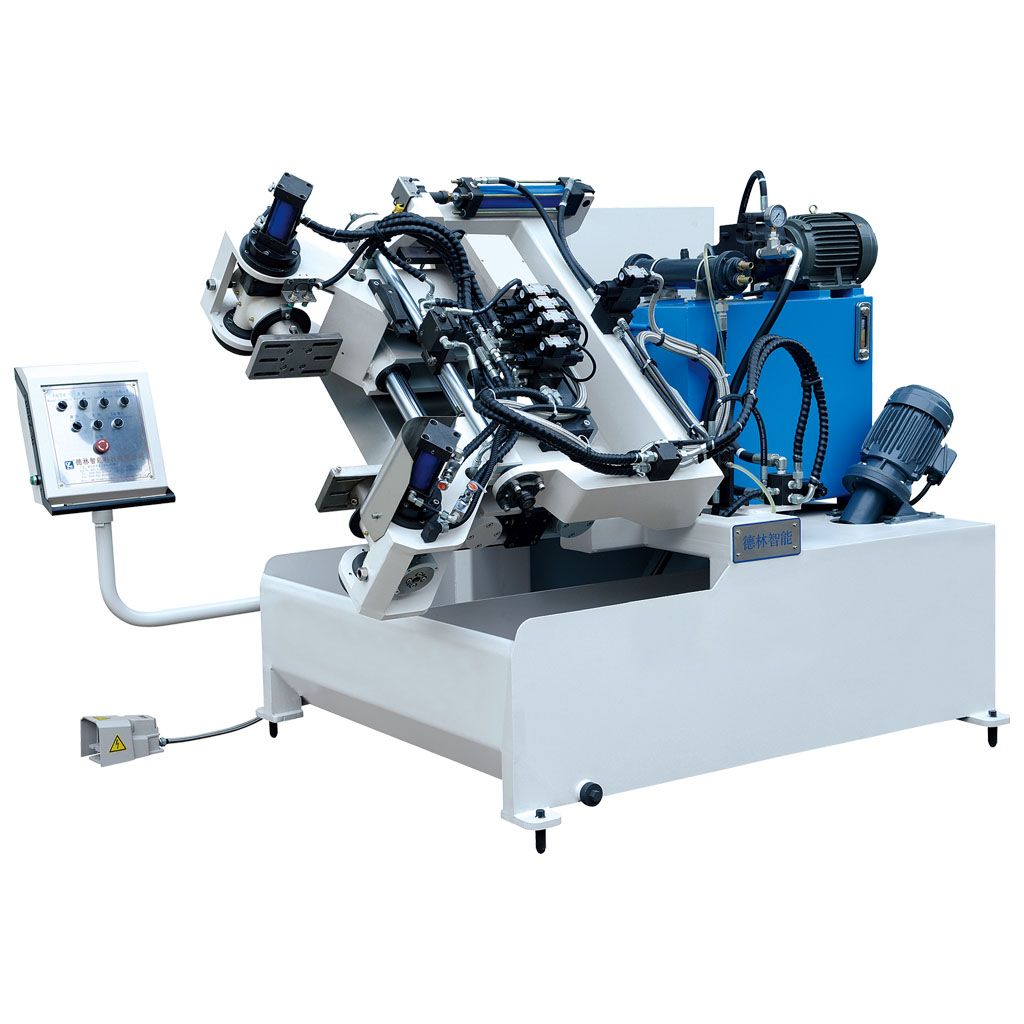

DLRT45

Delin

Adopt man-machine interface, real-time status display, menu input, wide range of process parameter adjustment, independent control system, intelligent parameter storage, easy fault checking, simple operation and low maintenance cost;

The upper and lower molds are clamped and the mold is rotated, so that the metal liquid can be evenly distributed, avoiding defects such as cold insulation, insufficient pouring and pores;

The cooling liquid is a mixed liquid of graphite powder and water. The graphite powder is attached to the sand core and is easy to demould. It is insoluble in water and has high temperature resistance.

Technical Parameters:

No. | Items | Parameters |

1 | Max. Size of Die | Φ450mm |

2 | Max. Weight of Die | 130kg |

3 | Max. Die Closing Stroke | ≤250mm |

4 | Hydraulic Pressure | 4-6MPa |

5 | Inclination for Side Pouring | 0-90˚ |

6 | Inclination for Frontal Pouring | 0-110˚ |

7 | Hydraulic Oil Volume | 163L |

8 | (Optional)Top Core Stroke | 20mm |

9 | Machine Power | 5.5kw |

10 | Net Weight | 1750kg |

11 | External Dimensions (L*W*H) | 2250*2160*1560mm |

Process composition:

Raise to a predetermined angle and place the sand core, step on the foot switch once (clamping) → casting → step on the foot switch once → timing after the clamping mechanism descends and returns to the original position → when the time is up, the mold is automatically opened → take out the product → switch Step on once → flip the mold clamping frame → mold rotation → mold lowering, rotating and cooling → mold rising → mold rotation return → mold clamping frame flipping back to position → worktable rising

Material selection:

1. The whole frame is made of QT450 castings, which is not easy to deform and has good toughness;

2. The lubricating part should be injected with general-purpose lithium-based grease with a dropping point of 193°C and a working penetration of 240. 3# general-purpose lithium-based grease lubricating oil is more resistant to high temperature than 2# and is used for heavy loads or vertical motor bearings. lubrication. The anti-wear hydraulic oil is 68#, and the new machine is replaced every three months, and then every eight months;

3. The coolant in the cooling pool is composed of graphite powder and water (about 850L);

4. High frequency quenching and chrome plating are used for mold clamping to improve surface hardness and durability;

5. The hydraulic system adopts Jiejia oil circuit, adopts Mitsubishi PLC and Schneider electric components, high-end configuration of first-line brands, quick response, and prolongs equipment life;

6. Equipped with Omron sensor to control mold clamping accuracy and low failure rate.

Our Service:

We have strict management system,complete quality guarantee system and fine pre-sale and after-sale service system.

1.Pre-sale Service System

Please do not hesitate to contact with us If you are interested in machine. We can design the machine you requirements.

2.After-sale Service System

24/7 on line,including mobile/wechat/whatsapp etc. Our technician is available to visit and go to your place,and they will help your side for installation,maintenance,and training.

3.Payment

30% Deposit by TT,and The rest 70% by photos or you can check the quality on our factory before they shipment.

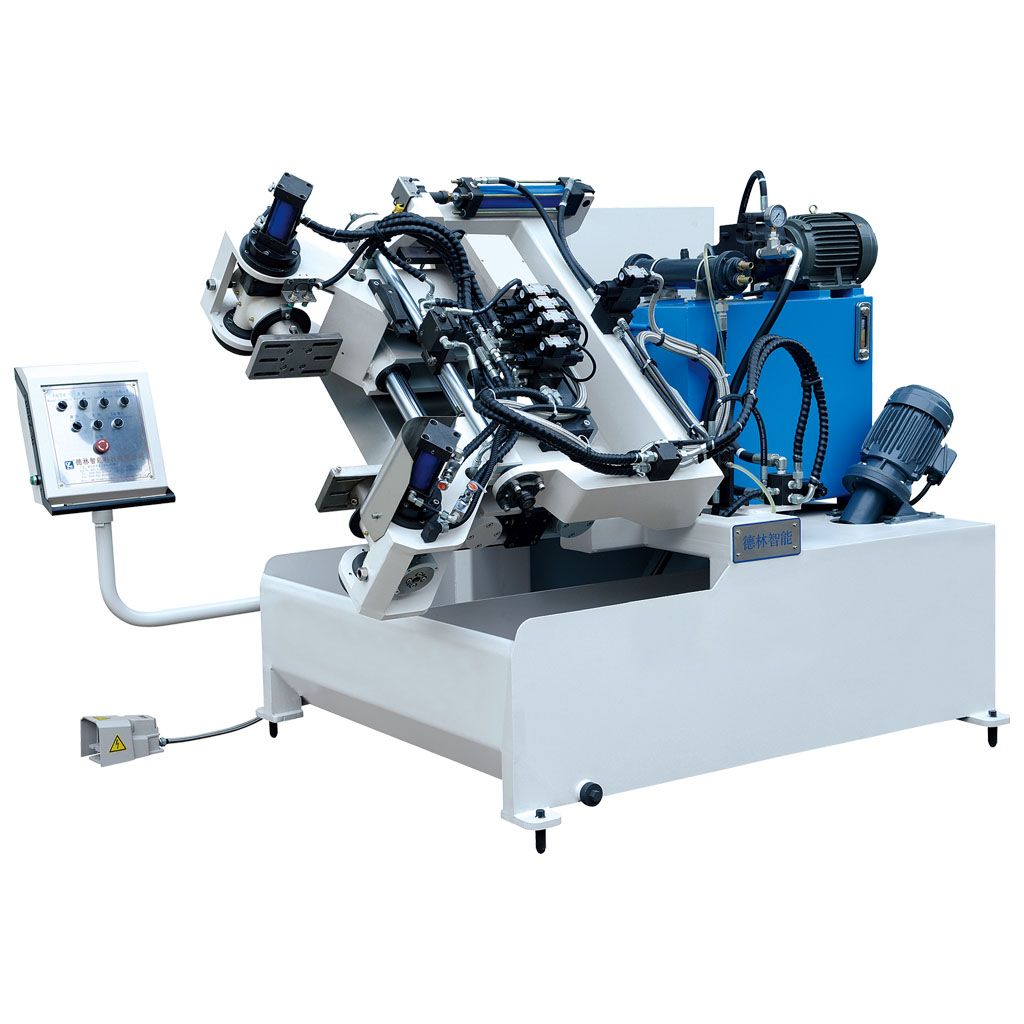

Adopt man-machine interface, real-time status display, menu input, wide range of process parameter adjustment, independent control system, intelligent parameter storage, easy fault checking, simple operation and low maintenance cost;

The upper and lower molds are clamped and the mold is rotated, so that the metal liquid can be evenly distributed, avoiding defects such as cold insulation, insufficient pouring and pores;

The cooling liquid is a mixed liquid of graphite powder and water. The graphite powder is attached to the sand core and is easy to demould. It is insoluble in water and has high temperature resistance.

Technical Parameters:

No. | Items | Parameters |

1 | Max. Size of Die | Φ450mm |

2 | Max. Weight of Die | 130kg |

3 | Max. Die Closing Stroke | ≤250mm |

4 | Hydraulic Pressure | 4-6MPa |

5 | Inclination for Side Pouring | 0-90˚ |

6 | Inclination for Frontal Pouring | 0-110˚ |

7 | Hydraulic Oil Volume | 163L |

8 | (Optional)Top Core Stroke | 20mm |

9 | Machine Power | 5.5kw |

10 | Net Weight | 1750kg |

11 | External Dimensions (L*W*H) | 2250*2160*1560mm |

Process composition:

Raise to a predetermined angle and place the sand core, step on the foot switch once (clamping) → casting → step on the foot switch once → timing after the clamping mechanism descends and returns to the original position → when the time is up, the mold is automatically opened → take out the product → switch Step on once → flip the mold clamping frame → mold rotation → mold lowering, rotating and cooling → mold rising → mold rotation return → mold clamping frame flipping back to position → worktable rising

Material selection:

1. The whole frame is made of QT450 castings, which is not easy to deform and has good toughness;

2. The lubricating part should be injected with general-purpose lithium-based grease with a dropping point of 193°C and a working penetration of 240. 3# general-purpose lithium-based grease lubricating oil is more resistant to high temperature than 2# and is used for heavy loads or vertical motor bearings. lubrication. The anti-wear hydraulic oil is 68#, and the new machine is replaced every three months, and then every eight months;

3. The coolant in the cooling pool is composed of graphite powder and water (about 850L);

4. High frequency quenching and chrome plating are used for mold clamping to improve surface hardness and durability;

5. The hydraulic system adopts Jiejia oil circuit, adopts Mitsubishi PLC and Schneider electric components, high-end configuration of first-line brands, quick response, and prolongs equipment life;

6. Equipped with Omron sensor to control mold clamping accuracy and low failure rate.

Our Service:

We have strict management system,complete quality guarantee system and fine pre-sale and after-sale service system.

1.Pre-sale Service System

Please do not hesitate to contact with us If you are interested in machine. We can design the machine you requirements.

2.After-sale Service System

24/7 on line,including mobile/wechat/whatsapp etc. Our technician is available to visit and go to your place,and they will help your side for installation,maintenance,and training.

3.Payment

30% Deposit by TT,and The rest 70% by photos or you can check the quality on our factory before they shipment.